A. Photobiological hydrogen production by cyanobacteria

1. Our grand design of large-scale photobiological H2 production utilizing mariculture-raised cyanobacteria

HP (In Japanese)

The global human population has an acute need for renew-able energy sources in order to mitigate the global climate change caused by increasing green-house gases in the atmosphere and to keep up with the dwindling fossil fuel supplies. Photobiological H2 production by cyanobacteria is considered to be a strong candidate for renewable energy production (Sakurai et al. 2013, 2010, 2007).

Characteristics of our grand design

- Huge energy source: The solar energy received on Earth’s surface exceeds global fossil fuel consumption by 6,000 times.

- Clean H2 energy: In our system, the raw material is H2O, and the products are H2 and O2. When used in fuel cells, the energy conversion efficiency is expected to be high (max. about 60%), and the product is H2O free from air pollution. The used cyanobacteria cells can be used as feeds for fishes.

- The production scale can be large: Considering that our current consumption of fossil fuels is about 20 times greater than our energy derived from foods (7.1 billion of capita, 2,000 kcal/day), we cannot expect too much energy from land crops. Accordingly, we are proposing large scale photobiological H2 production utilizing mariculture-raised cyanobacteria.

Fig. 1 Our future vision

Large scale photobiological H2 production by mariculture-raised cyanobacteria

The bioreactors are large flexible H2-barrier plastic bags (e.g. 25 x 200 m) containing fresh water based culture medium floating on the sea surface.

2. Nitrogenase-based H2 production system

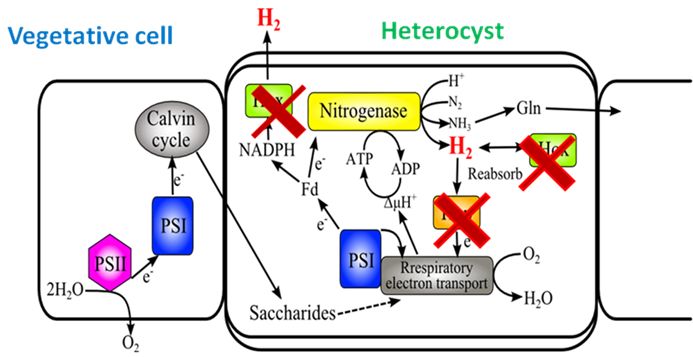

In our system, the enzyme of H2 production is nitrogenase (N2ase), and the presence of hydrogenases (Hup: uptake H2ase, and Hox: bidirectional H2ase) activity should be eliminated because it reabsorbs the produced H2 (Masukawa et al. 2002) (Fig. 2). We have created several H2ase mutants (ΔHup) from the heterocystous Nostoc sp. PCC 7120 (Masukawa et al. 2002, etc.) and sp. PCC 7422. The Nostoc sp. PCC 7422 ΔHup mutant accumulated H2 to 20-30% (v/v) in 3 to 8 days, and the efficiency of light energy conversion into H2 was 3.7% vs visible light (calculated to be about 1.7% vs. total solar radiation). When Nostoc sp. PCC 7422 ΔHup mutant cells were transferred to a combined N-free medium under 80% N2, H2 production activity declined in a few days by the sufficiency of the combined nitrogens due to active N2 fixation by N2ase (Yoshino et al. 2009). By decreasing N2 gas concentration to 0.5-1% in Ar + 5% CO2, the H2 production activity was maintained at high levels for more than several weeks. In some of the site-directed N2ase mutants, H2 produced was not decreased by N2 , indicating the possibility of the cost reduction of the filling gas (Ar). (Masukawa et al. 2012, 2010).

Fig. 2 Nitrogenase-based H2 production by heterocyst-forming cyanobacteria

Vegetative cells assimilate CO2 and produce saccharides by ordinary photosynthesis. Heterocysts do not evolve O2 because they have no PS II activity, and receive saccharides from vegetative cells. Heterocysts fix N2 to ammonia by nitrogenase (N2ase), and ammonium is used for glutamine (Gln) synthesis. The division of labors thus allows simultaneous operation of O2-evolving photosynthesis and O2-sensitive N2ase in the same filament of cyanobacteria. Fd: ferredoxin, Gln: glutamine, Hox: bidirectional H2ase, Hup: uptake H2ase, PSI: photosystem I, PSII: Photosystem II

3. Research and development of plastic bioreactors for future practical application

As pointed by W.A. Amos (http://www.nrel.gov/docs/fy04osti/35593.pdf, Updated CostAnalysis of Photobiological Hydrogen Production from Chlamydomonas reinhardtii Green Algae Report to N.R.E. Laboratory), for economic viability, the cost of bioreactors should not exceed several tens of $ per m2. We are developing inexpensive transparent flexible plastic bags (see Fig. 1) as the bioreactors (Kitashima et al., 2012).

Table 1 The permeability constants (Pm) and the heat stability of Wakhy bags (some of them up to 120oC, and others to 100oC)

Applicability in the future: Assuming the Pm value of 50 mL m-2 day-1 atm-1, the escape of the produced H2 from the bags in 60 days is calculated to be < 0.2% (Assumptions; H2 production efficiency: 1.2% vs. solar, initial gas: 50 cm in thickness).

Cyanobacteria culture in a Wakhy bag (35 x 50 cm) |

Gas sampling port for conveniently sampling gas in the bag (Japan patent 5294128) Applicant: Waseda University Inventors: H. Sakurai et al. |

Fig. The Wakhy plastic bag and the gas sampling ports are available from GL Science, Inc., Japan. (E-mail:[email protected]). For technical information write to Wakhy Laboratories, Inc., Japan (E-mail:[email protected]).

Publdications

- H. Sakuraia, H. Masukawa, M. Kitashima, K. Inoue (2013) Photobiological hydrogen production: Bioenergetics and challenges for its practical application. J. Photochem. Photobiol. C: Photochemistry Reviews 17: 1–25

- M. Kitashima, H. Masukawa, H. Sakurai, K. Inoue, (2012) Flexible Plastic Bioreactors for Photobiological Hydrogen Production by Hydrogenase-Deficient Cyanobacteria. Biosci. Biochem. Biotechnol. 76: 831-833

- H. Masukawa, M. Kitashima, K. Inoue, H. Sakurai, R.P. Hausinger (2012) Genetic engineering of cyanobacteria to enhance biohydrogen production from sunlight and water. AMBIO 41, suppl. (2) 169-173

- H. Masukawa, K. Inoue, H. Sakurai, C.P. Wolk, R.P. Hausinger (2010) Site-directed mutagenesis of the Anabaena sp. strain PCC 7120 nitrogenase active site to increase photobiological hydrogen production. Appl. Env. Microbiol. 76: 6741-6750

- H. Sakurai, H. Masukawa, M. Kitashima, K. Inoue (2010) A feasibility study of large-scale photobiological hydrogen production utilizing mariculture-raised cyanobacteria. Adv. Exp. Med. Biol. 675: 291-303

- H. Masukawa, Xh. Zhang, E. Yamazaki, S. Iwata, K. Nakamura, M. Mochimaru, K. Inoue, H. Sakurai (2009) Survey of the distribution of different types of nitrogenases and hydrogenases in heterocyst-forming cyanobactera. Mar. Biotechnol. 11: 397-409

- H. Masukawa, K. Inoue, H. Sakurai (2007) Effects of disruption of homocitrate synthase genes on photobiological hydrogen production and nitrogenase of Nostoc sp. PCC 7120, Appl. Env. Microbiol. 73: 7562-7570

- H. Sakurai, H. Masukawa (2007) Invited review: Promoting R & D in photobiological hydrogen production utilizing mariculture-raised cyanobacteria. Mar. Biotechnol. 9: 128-145

- F. Yoshino, H. Ikeda, H. Masukawa, H. Sakurai (2007) High photobiological hydrogen production activity of a Nostoc sp. PCC 7422 uptake hydrogenase-deficient mutant with high nitrogenase activity. Mar. Biotechnol. 9: 101-112

- Masukawa, M. Mochimaru, H. Sakurai (2002) Disruption of uptake hydrogenase gene, but not of bi-directional hydrogense gene leads to enhanced photobiological hydrogen production by the nitrogenase-fixing cyanobacterium Anabaena sp. PCC 7120. Appl. Microbiol. Biotechnol. 58: 618-624